ShiniKoroshi

Dept. of Shenanigans

The metal canister in the center is to house the fan and heat source. Here is where we need to do a little shopping for easy to assemble components. There are many combinations of product available.

For example....

A 4 inch (102mm) duct fan available on Amazon for $11 to $20

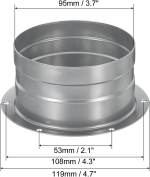

The fan would be connected to a flange duct connector ($8) that would be fastened to our raised floor.

The combined height of these two components will be about 9 inches (228mm). The heat source can be mounted in either the flange or the downstream side of the fan.

The heat source is a small *100w halogen lamp. Actual size .6inch x 2.25inch (15mm x 57mm) $3-$6

*100W may be too hot. I do know 50w and 75w are available.

There are many socket options for the E11 mini-candelabra bulbs. $3-$6

Don't forget that you will need a 140°F (60°C) thermal fuse. $2-$5

This is only one (on the fly) example of how you can get this together. Different fan may require a different coupling and mounting, etc. There are NO WRONG ideas and solutions. The point is maximizing the economy of either expense, effort and/or complication.

For example....

A 4 inch (102mm) duct fan available on Amazon for $11 to $20

The fan would be connected to a flange duct connector ($8) that would be fastened to our raised floor.

The combined height of these two components will be about 9 inches (228mm). The heat source can be mounted in either the flange or the downstream side of the fan.

The heat source is a small *100w halogen lamp. Actual size .6inch x 2.25inch (15mm x 57mm) $3-$6

*100W may be too hot. I do know 50w and 75w are available.

There are many socket options for the E11 mini-candelabra bulbs. $3-$6

Don't forget that you will need a 140°F (60°C) thermal fuse. $2-$5

This is only one (on the fly) example of how you can get this together. Different fan may require a different coupling and mounting, etc. There are NO WRONG ideas and solutions. The point is maximizing the economy of either expense, effort and/or complication.

Last edited: