Orson Carte

Well-Known Member

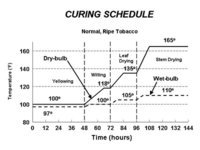

The 'Schedule' that I follow, and has been shown in previous postings, is this:

Following this schedule, Stem Drying requires 12 hours of gradual increase up to 78.8C then 36 hours at that temperature with an 18% RH. (That is, 48 hours on, following 'Leaf Drying').

So, it is perhaps still a little early to anticipate that your stems are dry enough to snap.

Following this schedule, Stem Drying requires 12 hours of gradual increase up to 78.8C then 36 hours at that temperature with an 18% RH. (That is, 48 hours on, following 'Leaf Drying').

So, it is perhaps still a little early to anticipate that your stems are dry enough to snap.