I have tried a number of ways to load my chamber and get a uniform cure. While taking advantage of space to get as much tobacco in the chamber as possible.

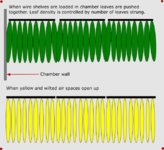

Wire shelving works best. I can hang my tobacco using wire under the shelf in advance before placing inside the chamber.

This allows for:

Saving time

Plenty of work space

Maximize load

Control density

Keep consistent

Hanging leaf outside of chamber

Wilting outside of chamber if desired

Easy loading of chamber

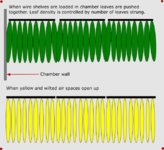

To yellow tobacco after a number of cures it is now my thought, that if tobacco is loaded with space between and around leaves start temperature should be low 90s.

The leaf yellows in 48 to 60 hours if ripe. The more ripe the tobacco the less time to yellow.

If tobacco is loaded tightly start temperature should be high 90s to 100F.

The leaf yellows in 48 to 60 hours if ripe. The more ripe the tobacco the less time to yellow.

If tobacco is very ripe in thought it has less moisture within a leaf & artificial moisture my be needed (water pan) to keep humidity acceptable for yellowing.

.

..

.

I adapted this method for this cure. In the future I will always use this method it works very well.

Loading the leaf in a uniform manner is important