leverhead

Well-Known Member

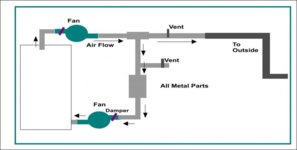

Yup! that's pretty much it. To go up the chimney, you might want to use a fan to keep a draft going and just vent into the inlet.

Remember this is ducting so the "valves" could be as simple as blast gates. Simple to install, use and set and they're relatively cheap. -·-

No. They are designed to be used in high volume air handling systems and work well in house vacuum systems. They leak a bit and could not be used for liquids. However in a normal air flow situation the leakage is minimal. Just Google "air blast gate" and you'll see several different ones pictured in both metal and plastic. I like them and use them freqauently.Am not familiar with a blast gate valve Johnlee1933 do they seal 100%

No. They are designed to be used in high volume air handling systems and work well in house vacuum systems. They leak a bit and could not be used for liquids. However in a normal air flow situation the leakage is minimal. Just Google "air blast gate" and you'll see several different ones pictured in both metal and plastic. I like them and use them freqauently.

No. Manually operated slide gate.Are you talking about something that is self opening by air movement? The one I saw required 90 psi to activate the solenoid.

When I worked that stuff I used a face mask for the dust. It got so thick on my classes I got to where I thought I was going blind. LOLripped 1 sheet of the backer board on my little table saw yesterday cut ok but was a dusty event had to hold my breath. Looking for Hygrowmeter now.

I got an industrial thing today for 24 bucks is used but looked good also put another one on my watch list. It was up for bid only had an hour & 6 minutes left and no bids than I got to looking at all the other ones and the time ran out with -0- bids. Cuss Cuss so I put it on the list for laterOver 3,000. Alot of them BuyNow with free shipping.

http://www.ebay.com/sch/i.html?_from=R40&_sacat=0&_nkw=hygrometer&_fscr=1

It'll ruin a counter sink too...When I worked that stuff I used a face mask for the dust. It got so thick on my classes I got to where I thought I was going blind. LOL

We discuss any variety of tobacco, as well as numerous approaches to growing, harvesting, curing, and finishing your crop. Our members will attempt to provide experience-based answers to your questions.